Teknic ndi mtsogoleri wapadziko lonse lapansi pakuchita masewera olimbitsa thupi, omwe ali ndi makasitomala kuyambira makampani akuluakulu opanga zida zamagetsi kupita kumakampani opanga magalimoto kuyambira pamalingaliro opanga, kupanga ndi kuyika.

Timapereka zinc die casting kuchokera pakupanga nkhungu ndi kuyezetsa, kupanga zinki, kumaliza, ndi kulongedza kuchokera pamapangidwe ovuta ndikusandutsa kukhala chinthu chomalizidwa.

Teknic akutsogolera makampani opanga zinc kufa zaka 10.Chiyambireni kukhazikitsidwa kwake, tasintha kukhala mtsogoleri wapamwamba kwambiri padziko lonse lapansi pogwiritsa ntchito ukadaulo wake komanso akatswiri aluso kuti apange zida zapamwamba kwambiri zakufa.Timayang'ana kwambiri pazabwino komanso kuthetsa mavuto ku China.pamaziko opangira Zinc Molding.

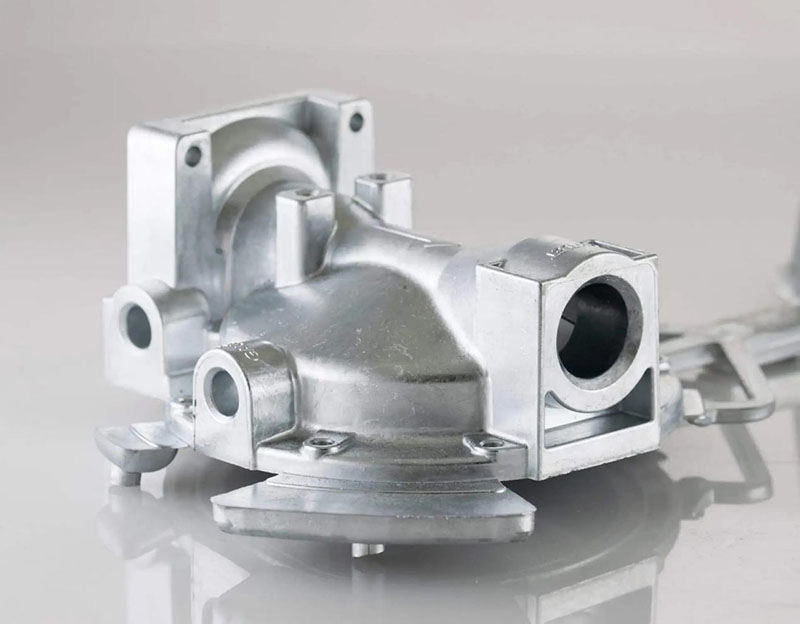

Mawonekedwe Ovuta & Kulekerera Kwambiri

Zinc die casting imapanga ma cavity angapo, mawonekedwe ovuta komanso kulolerana kwapafupi kuposa njira zina zambiri zopangira.Kuphatikiza pa kupanga maunivesite okwera kwambiri a magawo ofanana, amatulutsa kutentha kwamphamvu komanso kuvala zingwe zolimba zomwe zimakhala zokhazikika, ndikusunga zololera zapafupi kwambiri.

Njira yopangira ufa imapatsa opanga mwayi wopulumutsa ndalama pophatikiza zinthu zina kuti zikhale zopanga maukonde.Chifukwa chake, kuthekera kochotsa ntchito zachiwiri monga kukonza makina.Zinc die castings adapangidwa bwino ngati ma bearings (kuchotsa ma aloyi amkuwa), ma rivets, ndipo amatha kuyika ulusi.Chifukwa cha maubwino awa, ma kufa castings amapezeka m'mafakitale osiyanasiyana kuphatikiza magalimoto, zida zomangira, zamagetsi, zamasewera, ndi zina.

Tiyenera kuzindikira kuti kulolerana kwamakampani kumatha kukumana ndi / kapena kupitilira, ngati kuli kofunikira pamapangidwe a gawolo.Komabe, pali zinthu zambiri zomwe ziyenera kuganiziridwa, monga;mawonekedwe a gawolo, pomwe gawo lili mkati mwa chida, malo ake ndi otani ndi mbali zina za gawolo komanso ngati mukuyang'ana pamzere wolekanitsa.Poganizira za moyo wa zida ndi mtengo wake, ndikwabwino kulola kulolerana mowolowa manja ndi kulembera madera omwe alibe zokwanira, mawonekedwe kapena magwiridwe antchito komanso kumangitsa kulolerana kokha m'malo omwe kuli kofunikira.

Zine yathu ya die casting imasiyana kukula kwake kuyambira matani 100 mpaka 300, kupanga zida zopangira zinki zamapulogalamu otsika kapena apamwamba kwambiri.Titha kupanga zinki kutentha chipinda kufa kuponyera, zotayidwa-zinki otentha kapena ozizira chipinda mkulu kuthamanga kufa kuponyera, komanso zotayidwa kufa kuponyera.Kuyang'anira ndondomeko, kujambula m'mbali mwa atolankhani, ma robotiki, kuyerekezera koyenda, zida zosatha komanso kukonza zida zimagwiritsidwa ntchito kukulitsa moyo wa zida, kupulumutsa mtengo, nthawi, ndikupereka zida zapamwamba kwambiri.Kuchokera pamalingaliro a mbali ndi kufananiza bwino, mpaka kusonkhanitsa zinthu zomalizidwa.

Zinc Aloyi

Ndife otsogola pakupanga kwa kufa ku China.Akatswiri athu ophunzitsidwa bwino a Metallurgists amawonetsetsa kuti ma alloys onse amakwaniritsa zomwe amafunikira posanthula mosalekeza kwamankhwala ndi thupi.

Ma alloys athu akuphatikizapo:

Zinc: Zamak 3, 5, ndi 7.

Zinc-Aluminium: ZA-8, ZA-12, ndi ZA-27.

Zinc alloys ndi osavuta kuthamanga kwambiri.Iwo amapereka ductility mkulu, mphamvu mphamvu, ndipo mosavuta yokutidwa.Zinc alloys ali ndi malo otsika osungunuka kuposa aluminiyumu omwe angathandize kukonza moyo wakufa.

Ma alloys a ZA ndi zida zopangira zinki zomwe zimakhala ndi aluminiyamu yapamwamba kuposa ma aloyi wamba a zinc.Ma alloys awa ali ndi mphamvu zambiri komanso kuuma kwakukulu komanso kunyamula katundu.

Kuyesa kwa Zinc Mold Flow

Teknic imagwiritsa ntchito ukadaulo wodziwika bwino wa CAM wodziwika padziko lonse lapansi kukhathamiritsa kapangidwe ka zida ndi mtundu wa zinki.

Kuthekera koyerekeza kwa CAM kumapereka kumvetsetsa bwino kwa kudzazidwa kwa nkhungu ya jekeseni wa zinc, kulimba, makina amakina, kupsinjika kwamafuta ndi kupotoza.Zomwe zimayendetsedwa ndi menyu ndi makina ophatikizika olimba, mawonekedwe a CASD, ndi nkhokwe zambiri, CAM imapereka yankho lathunthu pamapangidwe, kupanga, ndi madipatimenti abwino.

Steel Injection Mold Castings

CNC Machining ndi Hog-outs

Direct Metal Laser Sintering (DMLS)

P-20 Zida

ZINC SURFACE FINISHING

Teknic idzayang'anira zofunikira zamakasitomala kuti zitsimikizire kuti magawo amakwaniritsa zofunikira munthawi yake komanso yotsika mtengo.

Kumaliza kwathu kwa zinc kumaphatikizapo:

Kupaka Powder (electrostatic application)

Paint Yonyowa

Chromate

E-Coat

Nickel wopanda Electroless

Chrome

Kuwunika kwa Silk ndi Stenciling

EMI/RFI Shielding

Surface Conditioning (kuwombera ndi kuphulitsa mikanda)